How To Match Skip Troweling Texture On Drywall Repair

Self-leveling underlayment. Information technology sounds soooooo easy, doesn't it?

You simply pour the leveling cement over the floor and the production then just levels itself all on its own.

Sort of similar…magic, correct?

Cocky-leveling underlayment is not what it seems

Self-leveling underlayment is, quite likely, the worst named product in the world of tile. Why?

What I tin can tell you is that self-leveling for tile floors takes a proficient deal of planning and training.

I include myself in the many installers that have but "moved lumps around." This means that the pour didn't go well and that we simply made a new loftier indicate in the floor without really flattening anything.

Even so, there is a need for these products and they have a place. In fact, with some advancements in technology, I expect them to become more and more pop.

This post contains chapter links. The site owner may earn a commission should you click on an affiliate link and make a purchase. Read more

Table of Contents (click to expand)

Table of contents

- Self-leveling underlayment is not what it seems

- Self-leveling underlayment has a vivid future

- Planning for a self-leveling underlayment pour

- Substrate

- Physical

- Wood subfloors

- Board

- Self-Leveling Underlayment for Wood Subfloors

- Rapid setting self-leveling underlayment

- Flat or Level?

- How apartment does it need to be?

- Floor flatness requirements for tiles nether 15 inches

- Flooring flatness requirements for tiles with at to the lowest degree ane side over 15 inches

- How apartment does it need to be?

- Special Circumstances

- Pouring over existing flooring

- Asbestos

- Moisture

- Substrate

- Preparing the floor prior to a self-leveling underlayment cascade

- Cleaning the flooring

- Grinding

- Flooring grinding tools

- DIY dust shroud

- DIY dust collecting cyclone

- Electric Sanders

- A uncomplicated examination

- Grinding

- How to care for seams and cracks prior to a cocky-leveling pour

- Concrete

- Wood

- Toilets, vents, and other holes and gaps

- Perimeter and Doorways

- Mapping out your floor prior to self-leveling

- Offset, locate the high point in the floor

- Flat or flat and level?

- Leveling pegs for cocky-leveling floors

- Where to identify the pins

- Setting the heights of your leveling pins

- Setting the height for a level flooring

- Beginning at the loftier bespeak

- Leveling the residual of the pins

- Self-leveling Lasers

- Setting your summit for an out-of-level floor

- Setting the rest of the pin heights

- Primer for self-leveling underlayment

- Read the instructions

- Note: Pour the leveler right abroad after priming

- Cleaning the flooring

- Preparing to pour self-leveling underlayment

- Time is everything!

- Plan your Path

- Staging area exterior the room being poured

- Mixing Station

- Location of the mixing station

- The path in between

- Tools for mixing self-leveling underlayment

- Mixing bucket

- Mixing saucepan (barrel)

- DIY mixing barrels

- Mixer

- Mixing paddle

- More buckets

- Mixing bucket

- Prepare upwardly your mixing station for success

- Prepare your water

- Why it's of import to measure the water

- Prepare the self-leveling bags

- Watch the temperature

- Prepare your water

- Pouring the self-leveling underlayment

- Tools for smoothing and gauging self-leveling underlayment

- Smoother

- Gauge rake

- Spiked roller

- Spiked shoes

- Pouring

- Mixing the cocky-leveling underlayment

- Pour IMMEDIATELY later mixing

- Pouring self-leveling underlayment onto the floor

- Wet border

- Larger Batches

- Smoothing

- The seams between batches

- Spiked roller

- Trouble areas

- Mixing the cocky-leveling underlayment

- Tools for smoothing and gauging self-leveling underlayment

- Afterwards your self-leveling underlayment pour

- Clean up

- Checking the flooring for flatness

- Low spots

- High spots

- Tying information technology all together

Self-leveling underlayment has a bright future

Tile keeps getting bigger and bigger. Where a 12x12 (30cm x 30cm) used to exist big now information technology's quite common to deal with tile that is 48 inches long (120cm).

Equally a issue, bigger tiles require flatter floors. Additionally, being able to employ these over wood subfloors is going to increase their usage. More on this later in the post.

With this mail service, I'thou going to share what I know. I don't consider myself an adept at cocky-leveling just I accept learned a lot.

And it all starts with knowing what you lot are getting yourself into.

Planning for a cocky-leveling underlayment cascade

So, how complicated tin can it be? Why not but mix the product and get?

For starters, simply selecting the product that yous want requires some consideration.

For instance, I looked at the sites of Mapei, Ardex, Schonox, Uzin, and Custom Edifice Products and counted no less than 9 unlike self-leveling underlayment products on each site. On 1 website, I counted 16!

Some self-leveling underlayments are cementitious while others are gypsum-based. Additionally, some are rapid-setting, some need metal lath reinforcement, etc.

Consequently, each product has its own purpose. Then, let's get into why you lot would pick ane over another.

Note: rather than spell out "self-leveling underlayment" all the time I volition use the manufacture-accepted initials of SLU at times throughout this mail service.

Substrate

Outset things first, what is the substrate that you want to flatten?

Substrate is a technical word which is referring to the surface that is being built over. Typically, it will either be concrete or wood. If it's woods, it should exist either plywood or OSB if you are planning on pouring an SLU over it.

The second thing to make up one's mind is what floor, if any, volition you exist installing on top of the leveling chemical compound? For this mail, nosotros volition patently presume tile.

So, just having those two pieces of information will narrow down the choices quite a bit.

Concrete

Having a concrete subfloor opens upwards the about self-leveling underlayment choices and that means more affordability, as well.

Beneath is a list of widely bachelor cocky-leveling underlayment products that can be used over physical. I consider them to be widely available because they tin can be purchased through many of the retail hardware store chains.

- Custom Building Products LevelLite

- Custom Building Products LevelQuik RS

- Mapei Self-Leveler Plus

- Mapei Ultraplan 1

- Tec 567 Contractor Class Self-Leveling Underlayment

Wood subfloors

Upwardly until recently, wood subfloors, either plywood or OSB, were not common to pour self-leveling over.

Lath

When it was done, you would need to install a metal or plastic lath production over the floor for reinforcement kickoff. Additionally, there were minimum thickness requirements. Anywhere, from one/four-1/2 inch and more than.

But now they have self-leveling underlayments that can be poured over a forest subfloor without any additional lath reinforcement. Plus, they can be poured as sparse as 1/iv inch and, depending on the production, even thinner.

Self-Leveling Underlayment for Wood Subfloors

Below is a list of self-leveling products that can be poured over woods subfloors. This list does non include all products in this category only these are the ones that I am enlightened of at the fourth dimension of this writing.

These products are not readily found in retail stores and would accept to be ordered in.

- Ardex Liquid Backerboard

- Henry's 542 Liquid Backerboard (Ardex owns Henry's)

- Custom Edifice Products LevelQuick Advance

- Custom Building Products LevelTech WSF

- Laticrete NXT Level Plus

- Mapei Planitex SLF

- Schonox APF

- Uzin NC 174

Rapid setting self-leveling underlayment

Withal another way of categorizing self-leveling underlayments. Some gear up up speedily and give you, maybe, 20 minutes of working time. While others can set up up much more slowly.

The rapid setting self-levelers tin put you nether a chip more than pressure as your doing the pour but the advantage is that they are ready to tile over in a affair of merely a couple of hours, in some cases.

On the other mitt, the slower setting SLU's tin can have more than a 24-hour interval before they're set to tile.

It seems to me that well-nigh of the self-leveling underlayments that can be applied over wood subfloors are of the rapid setting variety.

Flat or Level?

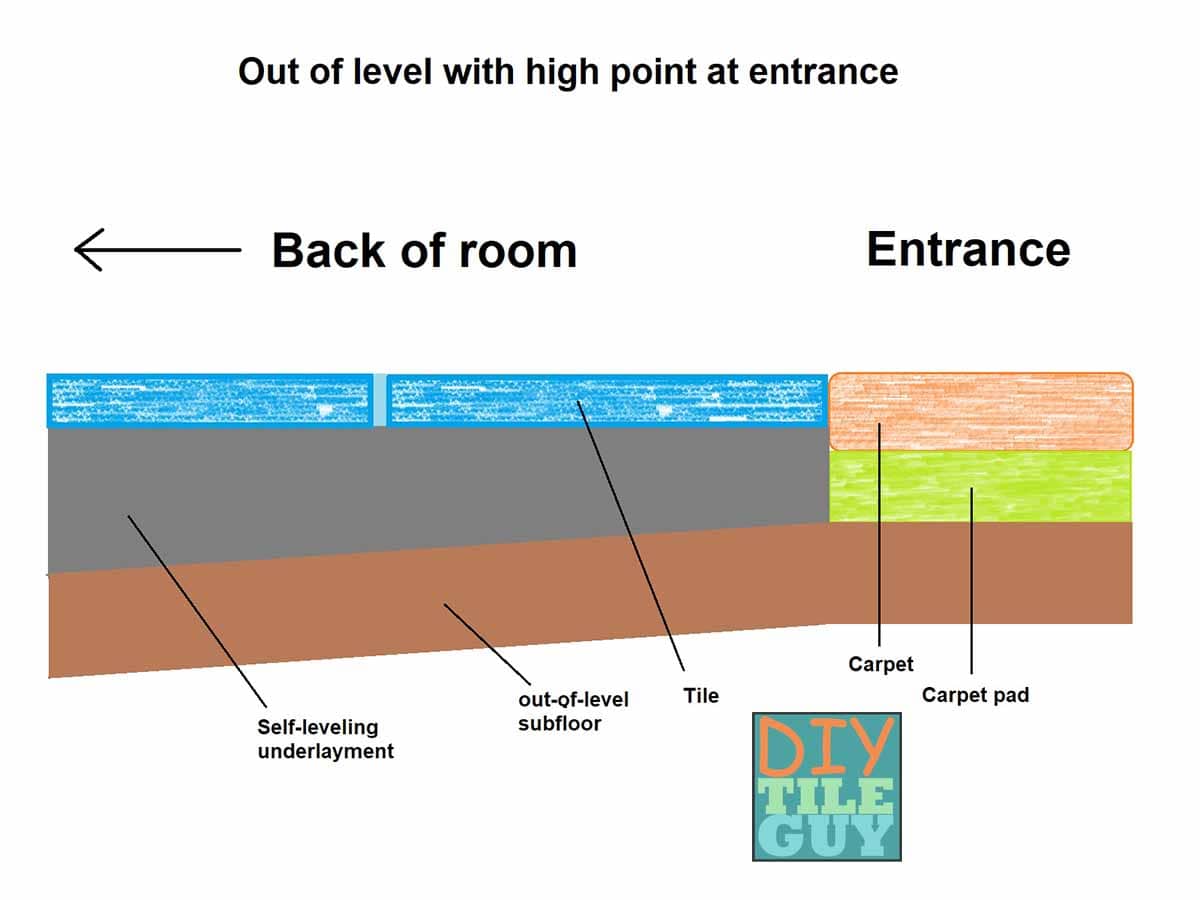

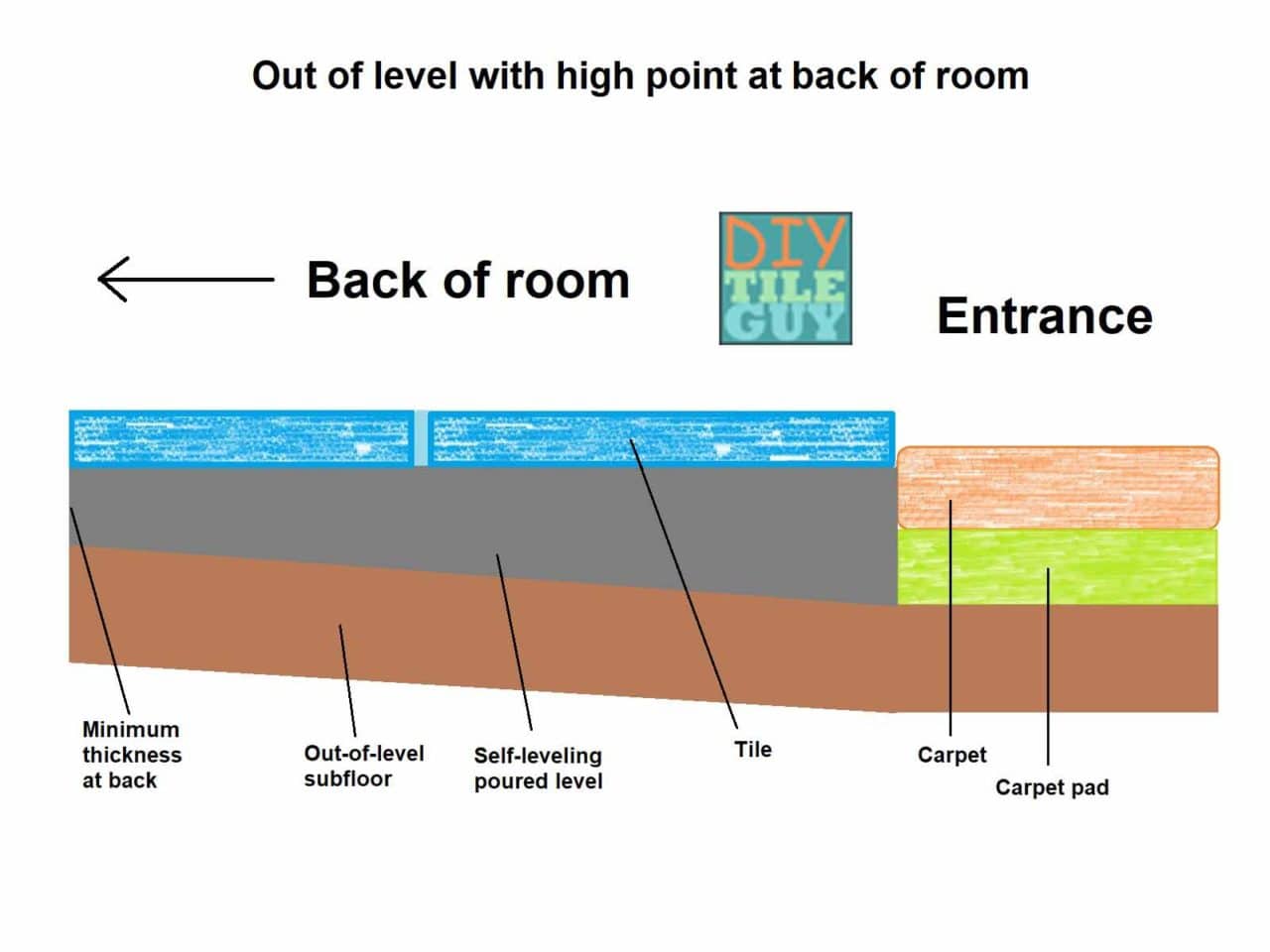

At present here's the question: Exercise yous want your flooring to be both flat and level or is it OK if information technology's but flat and maybe out-of-level?

Well, in a perfect globe the respond would be "both apartment and level!" Only we know that nosotros don't live in a perfect earth. Houses settle and some were never level, to begin with.

With this in heed, if you tin can get a apartment floor and so you lot need to consider that a win. Level is nice but flat is necessary.

However, when nosotros get into the method and techniques for flattening a floor you'll have a much easier time if y'all can gear up it upwardly to be a level pour.

How flat does it need to be?

The whole reason for using a leveler is to become things flat. Later on all, with tile getting bigger and bigger the consequences for not having a flat floor keep increasing, as well.

It simply and then happens to be that there is an contained body of experts that have set the standards for how flat a floor needs to be.

The name of these standards is American National Standard Specifications for the Installation of Ceramic Tile. We'll shorten this to ANSI for, what I think are, obvious reasons.

Additionally, at that place are actually two unlike answers on how flat a floor needs to exist and they depend on the size of the tile.

Floor flatness requirements for tiles nether xv inches

If your tile is under 15 inches on all sides then here is what the ANSI standard for floor flatness is:

For tiles with all edges shorter than fifteen in. (0.38 chiliad), the maximum allowable variation is no more than than 1/four in. in ten ft. (6mm in 3 m) and no more than than 1/xvi in. in i ft. (ane.6mm in 0.3 thou) from the required aeroplane, when measured from the high points in the surface.

ANSI A108.02 section four.1.four.3.1 Sub-floor surfaces

So, basically, information technology'south 1/4 inch of deviation in x ft. for tiles similar 12x12'southward, 8x8'southward, 6x12'south, etc.

And what if your tiles are bigger than that?

Floor flatness requirements for tiles with at least one side over 15 inches

Here'southward what the ANSI standard has to say in this example:

For tiles with at to the lowest degree ane edge 15 in. (0.38 thousand) or longer, the maximum allowable variation is no more than 1/viii in. in x ft. (3mm in iii g) and no more than 1/16 in. in 2 ft. (ane.6mm in 0.6 m) from the required airplane, when measured from the loftier points in the surface.

ANSI A108.02 section iv.1.iv.3.1 Sub-floor surfaces

So, if y'all are installing 12x24's, 16x16's, 6x24's, etc. and so you'll want your floor to exist inside i/eight inch in 10ft. That's a pretty apartment floor!

Well, at least you know what you're shooting for with your self-leveling underlayment pour so you tin can plan accordingly.

Special Circumstances

Earlier we get into the adjacent section, I want to quickly address some circumstances that are important but are out-of-the-scope of this already-lengthy mail.

Pouring over existing floor

There are reasons to pour cocky-leveling underlayment over existing flooring. It might be attached to the concrete really well, it might be a commercial awarding where this is the decision, or maybe information technology contains asbestos.

If you observe yourself in this state of affairs, I recommend y'all contact the technical departments of the products that you are working with and get some guidance from them on how to handle things.

Asbestos

This is always a tricky 1. If you discover yourself in a situation where there is older flooring information technology's important that you lot become it tested and discover out if information technology contains asbestos.

A lab tin oftentimes have an reply for you within 24 hours and information technology's not even that expensive to do.

If yous find out that the flooring does, indeed, incorporate asbestos then you lot won't be able to just rip out the floor. You may have to hire an abatement company.

Link to data on Asbestos from the Environmental Protection Agency.

Notwithstanding, many manufacturers take special primers that will let y'all to go over non-standard, troublesome substrates without removing them.

Examples of these products are:

- Mapei Eco Prim Grip

- Custom Building Products MBP

- Laticrete Prime number-Due north-Bond

Please contact the manufacturers to find out how to go along without removing the existing flooring.

Moisture

Moisture tin can cause bug for self-levelers and if you have some bug in this regard then you'll accept to practise some additional research on how to proceed.

If you are tiling a basement floor or are in an area with a high water table and so you'll want to brand sure that you lot are doing things the correct way.

A lot of times in that location are products recommended for sealing moisture prior to self-leveling a concrete floor.

You lot'll take to perform a couple of tests and see what you are up against. Again, this type of situation is outside the scope of this mail.

Preparing the floor prior to a cocky-leveling underlayment pour

Hopefully, you at present have an idea of what products to cull for your awarding. Now nosotros are going to have our focus to the actual floor that you want to flatten and prepare accordingly.

Cleaning the floor

For starters, every cocky-leveling production requires that the flooring be "solid, structurally audio, load-begetting, clean, complimentary of oil, wax, pigment, grease, asphalt, and other contaminants that might human action as a bond breaker."

All of the manufacturers accept a manner of proverb that exact same matter. And so what does this mean for you lot?

Grinding

The best fashion of preparing a flooring to have a self-leveling underlayment is past grinding the surface. I grind the surface of about every flooring that I tile.

No affair if your flooring is woods or physical, there is going to be paint, drywall compound, and whatever else on the surface.

Plus, it'southward really important that the leveling chemical compound bonds to the substrate.

Simply going over the flooring with a grinder is going to help ensure that the two surfaces bond similar they are supposed to.

Floor grinding tools

Depending on the size of the flooring, there are different size grinders. On large commercial jobs, they have ones that you can walk behind or even bulldoze around.

Merely near DIY'ers are going to take smaller floors to grind. Hither'due south what I apply:

- Electric circular grinder (7-inch, or 4-5 inch)

- Grinding disc (7-inch; four.5 inch)

- dust shroud (vii-inch; v-inch)

- Vacuum

- Dust Deputy

I understand that as a DIY'er yous're not going to have all of these specialty tools. Especially, the dust control measures.

The good news is that many more places nowadays are renting them out considering of the contempo tightening of laws in regards to both lead paint and silica dust. So bank check with your local tool rental stores commencement.

You might also consider that some of these tools will have multiple uses. For example, a iv-inch grinder with a diamond blade is a must-accept tool in every tile installer'south toolbox. In fact, nigh tilers deport more than one.

DIY Grinder Vacuum Attachment for Physical Grinding

DIY dust shroud

In the outcome that you can't rent the proper grit equipment, some have turned to making their own grit shroud for a grinder.

Here'due south an example of a guy that made one for nether $5.00 using a Tupperware chapeau, pipe insulation, and duct tape.

Keep in mind that you still need to habiliment a dust mask and proper protective equipment.

DIY dust collecting whirlwind

Only like you tin make a DIY dust shroud you can too make a DIY grit collector

The reason for the dust drove is because information technology keeps the filter in the vacuum from frequently clogging and filling the room with grit.

So, I'm featuring this video below that shows how to make a DIY grit collector. I actually like the one that Chris Notap makes improve but information technology is more piece of work and more parts.

How I Made A Dust Whirlwind for Under $two

Electrical Sanders

Electric sanders are another option but more geared towards wood subfloors. In fact, I used to use a belt sander before purchasing my dust command equipment.

You'll desire to apply very coarse sandpaper in the 30-xl grit range if yous can discover it.

A unproblematic test

Here'due south a very elementary exam that yous can perform that will tell you if your floor is ready to accept a cocky-leveling product over the top of it.

Drip some water over the floor and encounter how quickly it absorbs into the substrate. If information technology takes a minute or longer then it's non ready.

Here'southward a video from my Instagram that shows this process. Sorry, Facebook doesn't allow these videos to exist embedded in the post any longer:

If it absorbs quickly then it's time to movement on to the adjacent pace

How to treat seams and cracks prior to a cocky-leveling pour

Before a cascade, it's important to care for cracks and seams prior to self-leveling.

As a side note, I was disappointed with how vague some manufacturers were/are on this topic. I don't know how it helps their customers to take their lawyers write the instructions.

Concrete

For cracks in concrete, nigh manufacturers will want you lot to fill the crack with a floor patch product prior to pouring your SLU.

It should be mentioned that self-levelers are not a cleft-isolation solution. So if you have cracks that you would normally treat with a crack isolation membrane then that should now exist done on top of the cocky-leveling layer.

Furthermore, any control, movement, or cold joints will still need to be honored all the way up through to the tile.

Wood

Seams in plywood, or OSB, should exist filled the mode the SLU manufacturer specifies. Some manufacturers desire them filled with a flooring patching compound while others want an acrylic caulk.

Toilets, vents, and other holes and gaps

Look around for other holes and gaps. If you don't find them the self-leveler will.

Effectually the toilet flange is a mutual culprit for SLU to leak. Additionally, rut vents are always tough to seal around.

One way to handle these is by using spray foam to seal around these areas. Spray foam is easily available but tin can take a bit of a learning curve if it'south something that you lot aren't used to.

Another choice is to buy a specialty production like these circular toilet seals from a visitor called Edgeban. They are designed to seal around the toilet flange and proceed self-leveler from flowing nether, or over, the toilet flange. Additionally, this company as well makes i specifically designed for oestrus vents likewise.

I really can't stress this enough. Any hole, crack, or gap that remains volition be seen in the self-leveling layer. If it's small then it shouldn't be a big deal. But SLU will run downward larger holes much like water would.

Years ago, my friend and I were pouring cocky-leveling over some heat wires and didn't realize in that location was a hole effectually the toilet flange. The SLU ran straight down onto the washer and dryer that were in the basement. We never realized information technology until nosotros arrived the adjacent mean solar day and the homeowners brought this to our attending.

Some lessons are learned the hard fashion.

Perimeter and Doorways

If you lot've read my post "The One Affair Every Tile Installation Needs: Movement Joints" then y'all'll understand the importance of perimeter movement joints.

Not simply do we need this movement in the tile layer but we as well need it down at the underlayment level which, in this case, is the cocky-leveling layer.

After all, what good does information technology do to allow your tile to motility when they are installed over an underlayment which can't move?

So here are a few unlike ways to ensure motion around the perimeter of the room:

- Spray cream: Just like above, yous can spray a line of spray foam effectually the perimeter of the room.

- Sill Seal: Found in the window & door section of the hardware shop, sill seal is economical and simple to install. Only staple it to the wall and/or floor around the room to provide a barrier to the SLU from running all the mode to the wall.

- EdgeBan: This company, mentioned in a higher place, makes a product for going around the perimeter equally well.

- Border Strip Kits: Another production for going around the perimeter of the bath.

Both of the terminal two companies that I mentioned were started by fellow tile contractors.

All of these products above tin be used as a dam beyond the doorways also although the sill seal can be more than challenging to install over concrete.

Mapping out your floor prior to self-leveling

Now that you've sealed everything off it's time to offset figuring out how bad the floor is and what you have to do to it to get in flat.

Start, locate the loftier signal in the floor

This all begins by finding the loftier spot of your flooring.

The easiest way of finding the high spot is to use a laser and measure from the floor to the laser line. The shortest measurement wins.

Some other manner of doing it is to apply a longer level, or directly edge, to find out where the humps are.

In one case you figure out what spots are high and where they are in the room y'all'll and so exist able to determine if your goal is to have a apartment and level floor, or but one that is flat.

Flat or flat and level?

Back to this question again.

What determines whether you can make your flooring level is:

- Where the high point of the floor is in the room

- How bad the floor is in terms of flatness

- The thickness of the material in the adjoining room(s) that you are wanting to meet upward with

For example, take a await at the image above. You'll accept the best chance of having a level floor if your floor is reasonably flat or the loftier point is in the doorway.

However, If your high point is away from the door then most probable you'll have to settle for a flat and unlevel floor.

Leveling pegs for cocky-leveling floors

Next, it'southward fourth dimension to put leveling pins, or markers, over the floor and set them at the proper heights. These markers tell you how thick to cascade the flooring at whatever given spot.

Personally, I utilize these plastic agglutinative markers. I glue them to the floor and cutting them to the right height.

You tin as well use screws. This is the cheapest way and you can accommodate them upwardly and downwards if you don't quite get them prepare right the kickoff time.

Yet, the screws obviously won't work over a concrete floor. You'd have to get with the plastic adhesive ones for that state of affairs.

Where to identify the pins

For starters, I like to map out the floor in a filigree. I place the pins about every eighteen-inches apart, or so, and nearly 2 to half dozen-inches away from the walls.

The reason for setting them 18-inches apart is because that'south narrower than my smoothing tool which is about 21-inches long. That way, when I'g smoothing the floor I'm also hit 2 pins with every pass.

I want to credit Jamen with Icon Tile & Design for that particular tip. It'due south been useful.

We'll get more into the different tools down below.

Setting the heights of your leveling pins

Once you have a grid and know where you'll be placing the different pins information technology's and then fourth dimension to set the heights. And the heights will depend on if you are leveling, or not.

Setting the height for a level floor

Similar I mentioned earlier, you are going to have an easier time setting your heights if you are able to level the floor.

Start at the high point

The outset pin that you set should be at the high point of the floor.

For starters, you desire to know how thin your self-leveling product will go. Is it 1/4-inch? 1/8? Whatever it is, that's how thick you want to cut the first peg.

The SLU that I unremarkably employ tin get as thin as 1/8-inch. Furthermore, the base of the plastic adhesive pegs is near 3/16- thick and so that's how thick I commonly set the height for.

I just cutting the pin completely off and stick the base of it at the highest point of the flooring.

This is, of course, bold that you want the SLU as sparse every bit possible over the high point of the floor. If you need to raise the flooring up college then you would set the heights accordingly.

Leveling the residual of the pins

In one case you have the height determined yous will then fix every other peg level with that superlative.

The easiest way of doing this is with a laser.

Self-leveling Lasers

I'm a big fan of the PLS 180 cross-line light amplification by stimulated emission of radiation. I've had mine for years and information technology'south quite durable and broadcasts a nice sparse and level line. But information technology goes without saying that this isn't the cheapest option either.

Just a quick look through Amazon shows several affordable models including this one that is under $35.

If a light amplification by stimulated emission of radiation is out of the question then you'll have to utilise a level and level off of the high point of the flooring.

Here are the steps I have to set the pinnacle of the pins:

- Commencement thing is I set my light amplification by stimulated emission of radiation of the floor near a wall.

- Then I have the pin that I cutting off and set it on tiptop of the high bespeak so that it sticks straight up and downward

- Next, I utilize a Sharpie and marking the line where the laser is. This is now your primary marking. (This is seen in the gif above)

- Go to the next pin and hold the sharpie line of your marker on the laser line (gif below)

- Finally, trim the pin at the bottom of your master marker.

- Repeat

If that sounds a little confusing there is a quick video of the process posted above. It works whether yous're using plastic pins or screws.

Setting your acme for an out-of-level floor

For a apartment, yet out-of-level floor, you'll still need to make up one's mind the high point and go as thin as you can over this spot.

Additionally, yous'll besides want to take into account how high you can go in the doorway.

For instance, let's assume the flooring outside the bathroom is hardwood that is 3/4 inch thick and you lot want to lucifer the heights of the tile flooring and the hardwood.

If your tile is three/8 inch and yous need, say, 1/8 inch for mortar under the tile and so that ways yous'll take to be 1/2 inch beneath the hardwood.

So, you lot would so prepare the summit of the self-leveling peg to be 1/4 inch off of the flooring and that would leave 1/ii inch for tile+mortar.

Setting the residual of the pin heights

Once yous've determined the two points yous'll want to take a direct edge and set information technology across these 2 markers.

You would then trim all the markers in between these ii points to exist even with the bottom of the directly edge.

Furthermore, instead of a straight border, you could use a cord line. In this case, it might work better to tie the string to screws, if possible, fifty-fifty if you lot are using the adhesive pins.

This isn't going to exist like shooting fish in a barrel doing it this way and I'1000 not going to pretend that it is. The more fourth dimension yous take getting the different pins lined up and then they are in aeroplane the better off things are going to get.

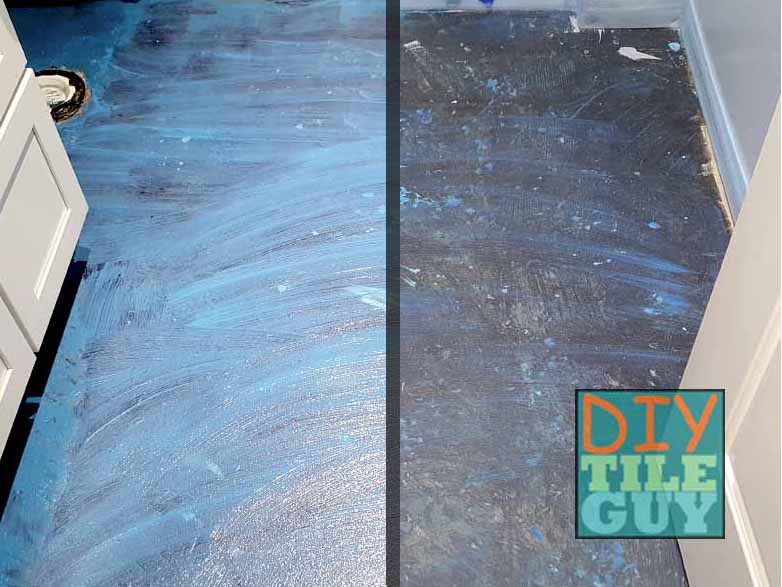

Primer for self-leveling underlayment

Finally! After you've got all of that done. With the filling of the holes, the perimeter movement, and setting the pin heights yous are ready to move onto the next stride! The primer

Aye, earlier pouring your cocky-leveling cement yous volition need a primer and every visitor has at least one that is to be used for their products.

In that location are near no scenarios where y'all wouldn't need a primer. Furthermore, if y'all don't employ one it'south nearly guaranteed that your floor is going to neglect.

Then, priming the floor is actually important.

Read the instructions

Not simply do you demand to get the right primer but sometimes you need to dilute the primer and sometimes you don't. Sometimes you'll demand to put on more one application and sometimes you won't.

Additionally, in that location are unlike ways manufacturers volition want you to apply the primer. These can vary from a paint roller, sponge, paintbrush, broom, etc.

The self-leveling primer should completely cover the floor but not exist puddling or besides thick.

Once yous've applied the primer over the floor, you'll need to wait for it to dry. And then your floor prep is consummate and it's time to motility onto mixing the self-leveler upward!

Note: Pour the leveler right away subsequently priming

Information technology's quite normal for manufacturers to have a time limit on when you lot can pour the leveler. For example, many will require the cocky-leveling to be poured within 24 hours of applying the primer.

Consequently, don't put the primer on if you aren't going to cascade the SLU over it right away.

Preparing to cascade self-leveling underlayment

You would think mixing the self-leveling underlayment would be pretty straightforward. Still, I can tell you that you demand to do some planning in this department also.

Once yous get-go pouring, there is no going back. You lot're committed and the easier you make things on yourself the ameliorate off your pour is going to go.

Time is everything!

This is especially true of the rapid setting SLU'due south which many of them are. And so yous need to have the mixing station ready to mix bag-afterwards-bag as efficiently every bit possible.

What y'all don't want to happen is to pour your first batch THEN get and get more water for the side by side batch, And so accept to walk out to your truck and get another purse of cocky-leveling, then forth.

As a event, I'm going to give you some tips on how to set up your mixing station, what tools you'll need, and how to plan for your pour.

First up, is to plan how you're going to go from your mixing station into the home or edifice.

Plan your Path

There are a few nuts that you need for a self-leveling pour. They are:

- A staging area outside the room

- Mixing station

- A path betwixt the two

Let's start with the staging area

Staging area outside the room being poured

One time you are inside the room and in the process of pouring, y'all'll need to keep some tools inside reach.

Did I mention that someone will have to really be inside the room where things are being poured? Once yous are in there, it'southward not piece of cake to motility in and out of the room that'due south getting the cocky-leveling.

The tools obviously tin can't exist in the room the unabridged fourth dimension because you won't have anywhere to put them once the leveler is covering the floor.

Then, I always put down some driblet cloths outside the doorway so cover them with plastic.

It's nice to have an 8ft x 8ft infinite for this just y'all'll have to work with what you can get. A lot of times, there just isn't that much space to be had.

Yous demand to be able to go on the different smoothers within attain. Also, you can put the bucket or barrel downwardly out here and it gives you a place to modify your footwear. More on this later.

Mixing Station

Side by side, you need a place to exist able to mix the numberless of cocky-leveling. This surface area will need to be large enough for:

- A mixing saucepan(s) or barrel

- A mixing drill

- Several buckets of h2o

- All the bags of leveler

- A saucepan of water to spin-off the mixing drill

What I do is place a tarp underneath all of those things. Go along in heed, y'all'll exist in a bit of a hurry and things can get only a piddling messy.

I retrieve about a 6x8 tarp for smaller jobs and a larger one for larger pours.

Location of the mixing station

Ideally, the mixing station would be right outside the room that'due south being poured.

However, considering of dust, mess, and space, this is not often possible, peculiarly with a renovation.

And so, you lot want the mixing station to exist as shut to the pour as possible. Additionally, the amount of help that you accept can cistron into this. More people assisting with the cascade can overcome greater distances to and from.

The path in between

You'll have a plastic tarp downwards for the mixing station and plastic down immediately outside the pour. It merely makes sense to take a covered path in between the two.

Anywhere that needs protection in betwixt these two areas will have to be addressed. It'southward not hard to rail things from the mixing area or baste leveler from carrying the saucepan to and from.

Personally, I work in remodels on a regular ground and I normally have a completely covered plastic path betwixt these 2 areas. Make sure that information technology isn't slippery though.

At present that you lot've figured out where you're mixing let's figure out what you'll need.

Tools for mixing self-leveling underlayment

First things outset, you need to have something to mix in. The typical choices are a bucket or a butt

Mixing bucket

A mixing saucepan is fine for smaller pours and pours where there isn't a lot of help. One person can comport the bucket dorsum-and-forth,

You're going to want one of the heavy-duty buckets. Sometimes these are called food-grade buckets. Self-leveling is heavy and the concluding thing that yous desire is a bucket splitting or breaking on you in the middle of a pour.

If you can detect yourself a six-gallon saucepan and then that is what I recommend.

A full bag of cocky-leveler will fit inside of a 5 gallon merely information technology will exist correct at the acme. Also, it volition overflow when you are mixing the leveler with water until yous go it mixed.

If you tin can discover a half-dozen or 7-gallon bucket that is the way to go, in my opinion.

Physical Subfloor Leveling in a Large Area MrYoucandoityourself

Mixing saucepan (barrel)

There are many mixing barrels designed just for self-leveling and they are what's recommended by people that do a lot of this.

Yous can mix ii bags at a time and pour both at once. There's a big advantage to beingness able to mix and pour multiple bags that I will get into in the "pouring" section below.

DIY mixing barrels

I've seen some guys use a large garbage can for mixing self-leveling underlayment.

Sometimes they put the tin on wheels and mix several bags at one time. I saw ane contractor put a PVC piping out of the bottom with a valve to turn information technology on and off.

They wheeled the can within the room and opened the valve so that the SLU came pouring out as they pushed the garbage can around the room.

So it doesn't injure to think outside the box when it comes to this.

Mixer

You're going to need a heavy-duty electric mixer for this project especially if you are mixing multiple bags at once.

I've used a cordless drill to mix many bags of thinset just I burned up this same drill trying to mix cocky-leveling underlayment. So, unless y'all have 1 of the newer heavy-duty 1/ii inch drills I would stick with something corded.

I've had good success with this Milwaukee hole hawg and you should probably exist able to rent something like this for a day. Whatsoever you lot go, it'll have to spin at a minimum of 650 RPM.

Mixing paddle

The mixing paddle is important too. The "egg-beater" style is what I've seen recommended and the oval shape if you are using a mixing barrel or if the bottom of your bucket isn't apartment.

These types don't let a lot of air in while mixing. You'll need one long enough to bear on the lesser of your mixing container.

More buckets

You'll also need several more than buckets and a measuring container for h2o

This covers the tools required for mixing. We'll get into the pouring and smoothing tools later.

Set your mixing station for success

The final thing that I want to cover for preparations is how to set your mixing station as it's disquisitional that this area runs smoothly and efficiently.

It's important that you have everything staged and fix so y'all don't waste time mixing more leveler while y'all have part of the pour already spread out on the floor and setting up

Then information technology all begins with the water

Prepare your water

For smaller pours, I like to have the water all gear up measured into several different buckets.

For instance, if I'm pouring four bags of cocky-leveling underlayment, I will have four buckets of water ready to get with the proper amount of h2o already premeasured in each bucket.

And then, as shortly every bit I'm done with the first saucepan, I bring it out to the mixing station, dump the premeasured water in, dump the bag of leveler in, and start mixing the next batch.

On larger pours, it'due south more mutual to have a large butt, or garbage can, full of h2o. Then, you desire to have a designated container to dunk in this barrel that volition quickly exist able to effigy out the correct amount of water.

One tip that someone gave me was to take a bucket with a hole cutting in it so any excess water will rapidly spill out leaving you with a proper amount of measured water remaining.

Why information technology's important to measure the water

What I practise is find out how much water the manufacturer recommends for their leveler. If it's a range, then I get with the high end of the range but not over.

If the leveler has bubbles, or foam, at the tiptop then that means that too much water was added.

Too little h2o means that the product won't flow and flatten out.

Basically, you want to spend as little time as possible fetching and measuring your water. The more than you can save steps in this regard the meliorate your pour will get.

Furthermore, the last affair that you want to do is add some h2o, so the leveler, then mix, determine it needs more water, add more h2o, more than mixing, etc.

Doing this will give you inconsistent batches of self-leveling and they won't flow together properly. Also, it takes more than time to mix in this manner.

Prepare the self-leveling bags

In addition to having the water ready to go, y'all'll also want the bags of self-level staged at the mixing station.

On a smaller pour, I will have each bag nearby with the top already cut off of the bag. As a result, all I take to practice is grab the bag and cascade it into the bucket.

For bigger pours, you lot'll probably have the bags stacked to relieve space but they need to be nearby and, hopefully, y'all'll take the manpower so that you aren't waiting for the bags to be readied.

Watch the temperature

One last thing to account for is the temperature. You lot tin't have the bags sitting out in the sunday getting hot as this volition cause them to set upwards even more than quickly.

And then keep the bags out of the sun and away from heat vents, etc. The aforementioned goes for monitoring the temperature of the water. Yous want clean and absurd water for your mixing station.

Pouring the cocky-leveling underlayment

Finally, you've cleaned your floor, plugged any gaps and holes, figured out the heights that you want to hit, and have a mode to mix and transport the cocky-leveler into the business firm, or edifice, quickly.

Let's get over the tools that are used to gauge and smooth the self-leveling underlayment out.

Tools for smoothing and gauging self-leveling underlayment

Smoother

A smoothing tool is probably the one must-have tool that you'll need.

Once the leveler is poured over the floor, you lot have to be able to button information technology around to the areas that need more leveler and remove information technology from areas that have too much.

This is one of the tasks of the smoothing tool. The other chore is to go over the top of the leveler and smoothen out any lines or inconsistencies.

Earlier I purchased a proper smoothing tool I used to use a floor duster. This worked to push the leveler around just didn't piece of work every bit well at the smoothing function.

Approximate rake

Basically, a gauge rake for self-leveling underlayment is a tool that has a crossbar, usually 24-36 inches, or so, and lets a certain corporeality of leveler laissez passer underneath it.

It does this past having an adjustable commodities on each stop. Typically, these bolts will adjust anywhere from ane/16 inch to 2-inches.

I don't have a lot of feel with a guess rake because I map out my floors with leveling pins.

Information technology'due south kind of a nice tool if you lot are not using leveling markers. You can spread out about the right amount of leveler over the floor and fine-tune information technology later.

Spiked roller

The spiked roller is my favorite cocky-leveling tool. It's exactly what it sounds like. A roller, similar a paint roller, with plastic spikes all over it.

How could this be a helpful tool? What it does is breaks the surface tension of the leveler. Doing this helps even out the seams between the pours. We'll get into more about how to utilize, not merely this tool but the others after.

One thing about this is if you take a deeper pour, one that'southward deeper than the spikes, so this tool won't help you.

So, if you're roller has 3/iv inch spikes but you're pouring 1-inch deep then this tool is going to be ineffective. You'll exist meliorate off with a gauge rake and smoother.

Spiked shoes

The last tool that I desire to cover is spiked shoes. Why would y'all want spiked shoes? Because y'all'll become the all-time results if yous can walk around in the room.

Spiked shoes are, simply, shoes with spikes on the lesser. They brand slip-on spike shoes that you tin can slip on over your existing shoes.

The advantage of this is that yous can sideslip them on and off with little effort.

However, almost of the spiked shoes that I see that are made specifically for cocky-leveling underlayment, or other types of coatings, are steel spikes.

If y'all are pouring over heat wires then you can't wear these. I went out and bought bodily cleats that athletes would vesture. I just looked for rubber cleats and a blueprint that had every bit few spikes every bit possible.

Pouring

We've arrived at the department that covers the actual pouring of the self-leveling underlayment.

Furthermore, every bit I mentioned previously, in that location's more to information technology than simply pouring the leveler over the floor and watching it "seek its own level."

Mixing the self-leveling underlayment

We've already covered how to gear up a mixing station and preparing to mix.

When it comes fourth dimension to actually mix the production and pour, you'll desire to add your water, already premeasured, into a mixing bucket or barrel first.

Once the water is added, go alee and add the entire bag of self-leveling underlayment to the bucket.

So mix it with your electrical mixer and egg beater-style mixing paddle. Well-nigh manufacturers want their product mixed for 2-iii minutes at a minimum of 650 RPMs. That's considered high speed.

More than likely, you'll be pressed for time at this stage. But I want to discourage y'all from cutting the mixing time brusk. Two to iii minutes of mixing can seem like a long time.

However, in addition to the strength of the product, mixing it for this long makes the cocky-leveling underlayment flow smoother and y'all'll take an easier time with it.

I highly recommend mixing for a minimum of two minutes and moving the mixer around the lesser to get brand sure every part of the saucepan gets mixed.

Cascade IMMEDIATELY after mixing

Once the product has been mixed for the proper corporeality of time it's time to pour. Make sure that y'all cascade it immediately afterward mixing.

Don't let the leveler sit in the bucket. Don't mix more buckets and then come dorsum and remix just prior to pouring.

Once it'due south mixed, bring it into the room and start pouring. Time is non on your side at this signal.

Pouring self-leveling underlayment onto the flooring

Typically, yous'll want to offset pouring towards the back of the room and work your style towards the door

Move the saucepan, or barrel, as you pour. Don't just dump it all in one spot and figure on moving it after.

Rather, movement the saucepan as your pouring around the room.

Wet edge

In general, you have near x-20 minutes of working fourth dimension with self-leveling underlayment.

Furthermore, each batch is going to be drying and setting upwardly on its own schedule. So, if information technology takes you two minutes between batches, the showtime batch is going to exist two minutes alee of the second batch.

This is why it'south important to make certain that when the second batch of self-leveling is poured that it completely meets up with the edge of the first batch.

This is what it means to maintain a "wet edge."

You don't desire batch number iii, or 4, to meet up with the first edge every bit they can exist v minutes autonomously in their dry times or more.

And so, maintain a moisture edge at all times. The edge of the pour should e'er be from the well-nigh recent batch

Larger Batches

Making larger batches isn't but for larger pours. Another reason is so that you don't have to bargain with keeping a wet edge.

If you tin mix up the amount of self-leveling cement that you will need for the entire room in one batch then that's a big advantage over having to marry ii, or several, batches together.

This is i of the pluses backside mixing multiple batches in a barrel.

Smoothing

Once you start getting the leveler poured on the floor yous'll want to outset moving it around over your height markers and smoothing information technology out.

Hopefully, you accept the manpower to have 1 person smoothing and another bringing the self-leveling in and pouring.

If you don't, we'll presume it's a small pour, and you'll but have to mix and pour the buckets equally quickly equally y'all tin then spend the fourth dimension to smooth and flatten.

One time the product is spread out at approximately the right height (according to the leveling pins) and so it's time to smoothen things out.

Anywhere you lot've moved the leveler around is a identify that is likely to show some unevenness. This is where you lot'll desire to polish things over by lightly gliding the smoother over the surface.

Pouring Self Leveling over a Bathroom Floor

The seams betwixt batches

Some other area that's mutual to become unevenness is in the seam between two different batches.

So you'll want to make sure to pay attention to these areas also. This is as well a adept spot for the spiked roller.

Spiked roller

Once you've spread the leveler around at the right height and smoothed over the unabridged floor, I like to run the spiked roller over everything.

Some people can get everything with the smoother but I've plant the spiked roller to be a valuable tool for evening things out.

I notice that the roller tin can help alloy the uneven areas that I might accept missed with the smoother.

I simply wheel the roller over the entire surface of the freshly poured self-leveling underlayment paying special attention to the seams of the pours and other areas that I may have moved around.

Problem areas

At that place are always certain areas that tin can create problems. Typically, it's tight areas where it's difficult to get tools behind to smoothen.

Areas like between the toilet flange and the wall. Also, behind a rut vent.

I've found that if I placed a leveling pivot in these areas that information technology'due south easier to gauge the height of the leveler.

Also, having a modest blade, like a iv-inch flexible taping knife, to smooth over tight areas past hand can be valuable.

These are areas that are usually hard to judge the height of and it's easy to go them likewise loftier or besides low.

If it'southward going to be ane, or the other, y'all want these spots to be too low as opposed to too high. Y'all can e'er fill up in too depression using the procedure below

Additionally, I recall smaller areas, like a bathroom, could be better served past having a smaller spiked roller, like the pigment roller size, rather than the larger ones like I currently own.

After your self-leveling underlayment pour

Clean upwardly

Make clean up your tools quickly as the leveler volition dry out fast. It'll take a bit of time to clean up your tools, mixing station, throw everything away, etc.

Checking the floor for flatness

Once the self-leveling underlayment is reasonably dry out, yous tin check the floor with a straightedge and see how apartment that y'all got it. Hopefully, it's perfect but commonly information technology will need a little fine-tuning.

Every bit good as information technology looked when it was wet, once it's dry out information technology will starting time to evidence its imperfections.

Low spots

Low spots are the easiest to accommodate and you tin mix up some a fast-drying patching product and fill these in. Something like Plume Finish from Ardex or Mapei's Planipatch works great for this.

High spots

If you have whatever high spots you might be able to scrape them off if you get to information technology quickly enough. Even if you lot scrape them too low yous tin can ever fill them in using the procedure above.

Otherwise, grinding is always an pick. Information technology's no fun to grind at this point in the project only you need to go rid of the high spots.

Tying information technology all together

Hopefully, I've helped to dispel the misconception that working with self-leveling underlayment is easy. Information technology doesn't practice all the work.

In fact, the more work and preparation that you do prior to your pour the amend things will go.

I hope things go well and please inquire whatsoever questions in the comments below.

How To Match Skip Troweling Texture On Drywall Repair,

Source: https://www.diytileguy.com/self-leveling-underlayment/

Posted by: herbertxylaw1937.blogspot.com

0 Response to "How To Match Skip Troweling Texture On Drywall Repair"

Post a Comment